Quality Control

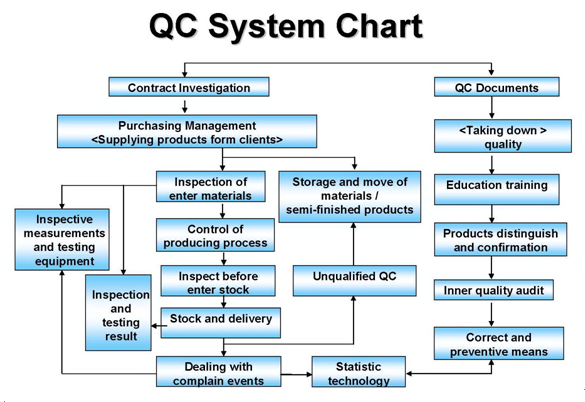

At Hongfa Industry Group, quality control is embedded in every stage of the manufacturing process, reflecting the company’s unwavering commitment to delivering "high-quality products and excellent service." The rigorous quality management system ensures that all construction machinery meets national and international standards, while also exceeding customer expectations for reliability and performance.

Quality Management Framework

- Standards Compliance

- All products adhere to Chinese national standards (GB) and are continuously updated to align with international norms (e.g., ISO 9001, CE certification for export markets).

- Compliance covers mechanical performance, safety protocols, energy efficiency, and environmental sustainability.

- Full-Lifecycle Quality Control

- Raw Material Inspection: Strict vetting of suppliers to ensure materials (e.g., steel, electronic components) meet physical, chemical, and mechanical property requirements.

- In-Process Monitoring: Real-time checks during production via 523 sets of precision inspection equipment, including coordinate measuring machines (CMM), non-destructive testing (NDT), and load testing systems.

- Final Product Testing: Every machine undergoes 100% functional testing, such as durability trials, performance simulations, and safety audits, before leaving the factory.

- Post-Sales Feedback: Regular customer surveys and after-sales service data are analyzed to identify improvement opportunities.

Key Quality Control Measures

- Advanced Equipment & Technology

- Utilizes automated inspection systems (e.g., laser scanning, robotic testing arms) to detect dimensional inaccuracies or structural flaws with micron-level precision.

- Employs statistical process control (SPC) to monitor production variability and optimize processes in real time.

- Dedicated Quality Teams

- Quality Assurance (QA) Department: Oversees system design, documentation, and compliance audits.

- Quality Control (QC) Teams: Composed of senior technicians and inspectors, conducting on-site checks at each production phase.

- Cross-Functional Collaboration: Engineers, production managers, and QC staff collaborate to resolve quality issues and implement preventive measures.

- Continuous Improvement

- Regular root cause analysis (RCA) for non-conformities, driving corrective actions and process enhancements.

- Participates in industry quality benchmarking and adopts best practices from global leaders.

Certifications & Accreditations

- ISO 9001:2015 Certified: Demonstrates adherence to international quality management standards.

- CE Certification: Ensures products meet safety, health, and environmental requirements for the European Union.

- Other Compliance: Meets regional standards in key markets (e.g., SONCAP for Nigeria, SASO for Saudi Arabia), facilitating seamless global distribution.

Customer-Centric Quality Assurance

- Pre-Sales Support: Technical consultations to tailor solutions to client needs, ensuring the right product specifications.

- After-Sales Service: Prompt maintenance, spare parts supply, and operator training to sustain product performance.

- Warranty & Liability: Backed by a comprehensive warranty policy and liability coverage, reinforcing trust with customers.

Sustainability in Quality Control

- Integrates environmental criteria into quality assessments, such as reducing noise emissions, minimizing energy consumption, and using recyclable materials.

- Regularly updates quality protocols to align with evolving green manufacturing trends (e.g., low-carbon production processes).

Conclusion

Hongfa Industry Group’s quality control system is a testament to its "quality-first" philosophy, combining technological rigor, skilled personnel, and a culture of continuous improvement. By ensuring every product meets the highest standards, the company not only strengthens its market leadership but also builds long-term partnerships with customers worldwide, rooted in reliability and excellence.

Hongfa Industry Group’s quality control system is a testament to its "quality-first" philosophy, combining technological rigor, skilled personnel, and a culture of continuous improvement. By ensuring every product meets the highest standards, the company not only strengthens its market leadership but also builds long-term partnerships with customers worldwide, rooted in reliability and excellence.