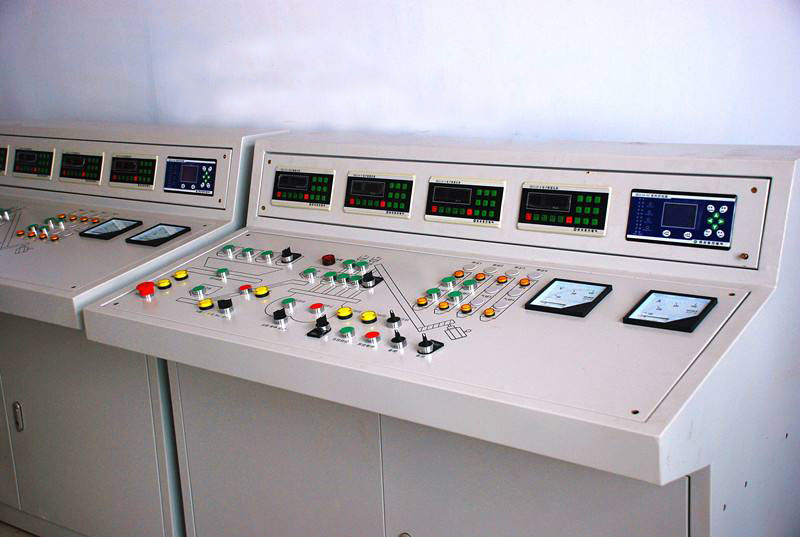

Concrete batching plant control system

MOQ:1 set

Driving power:AC 380V

Baud rate:115200

Are You Looking For?

Brief introduction:

The automatic control system of concrete mixing station is widely used in large and medium-sized concrete mixing station/building production equipment. The system is an intelligent automatic control management system which integrates control, management and network. The system adopts the characteristics of humanized design, synchronous operation of graphics and texts, high automation, strong anti-interference ability, high accuracy of batching, stable performance and simple operation. The computer control system consists of PC automatic control system, programmable logic controller (PLC) input and output unit, communication module, weighing module and control cabinet group. Soft and hard double interlocking control and protection function mode is adopted in the design of the system, which further improves the reliability of the system in long-term operation. In the aspect of production control, both the upper computer and the control cabinet have the functions of manual automatic independent control, operation monitoring information prompt, overshoot, on-line fault automatic detection, alarm, data backup, report printing and etc.

Technical data:

Driving power | AC 380V±15%, 50Hz/60Hz |

Working voltage | AC 220V±15%, 50Hz/60Hz |

Baud rate | 115200 |

Communication mode | RS232/RS485 |

User Interface | PC industrial computer bus control |

Static accuracy | ≤±0.5% |

Dynamic Accuracy | 1. Aggregate (Size ≤80mm) ≤±2% |

2. Cement, fly ash, slag powder, powder additives, water, liquid additives,slice ice≤±1% |

Advantage:

1. Humanized design, full dynamic simulation production screen, real-time monitoring, clear at a glance.

2. Open authorization setting for the discharge process, flexible and convenient.

3. To add and reduce water at any time in the production process, easy to control the quality.

4. Flexible operation, you can click the mouse to complete all manual processes in the computer screen.

5. Precise automatic calculation and correction of moisture content to further improve the quality of concrete.6. Industrial control computer has strong anti-interference ability and is reliable and stable.

7. Powerful out-of-tolerance alarm function to facilitate production monitoring.

8. Communication baud rate is high, batching speed is fast, stable and accurate.

9. Automatic correction and compensation of the technical difference of fast, medium and slow three-way speed proportioning can further improve the proportion accuracy and production efficiency.

10. Dual backup of the system and all production data ensures the stability of production and makes users safe and secure.

11. Task sheet input and scheduling are simple and fast, and operate on the same screen.

12. Manual batching, computer automatically records all kinds of material consumption statistics of manual batching, improve material consumption statistics.

13. Automatic batching can be suspended at any time without affecting the operation of other batching processes.

14. Permission type user management, operator access password login, prevent unauthorized personnel operating system, safe and reliable.

Leave Message

If you have any problems or questions about our products or need our support and assistance, please feel free to write us, we will reply to you within 24 hours, and never reveal your information to the third party. Thank you!